Custom manufactured extruded plastic lighting lenses add unique style and elegance to any lighting project. Lianzhen can help you choose the right materials, the right level of diffusion, light transmission, and assist in eliminating pixelization problems based on your project’s exclusive specifications.

For over 70 years,Lianzhen has been extruding acrylic light diffusers for lighting applications. The lighting industry has recently begun to transition into more energy-efficient LED fixtures,and we are part of this technology trend. We’ve been working with material suppliers and our customers to develop specific formulations for use in improved acrylic and polycarbonate extrusions, extruded LED lenses, LED light diffuser acrylic lenses, LED light lens covers, reflectors, and dust covers.

What are Custom Lighting Extrusions?

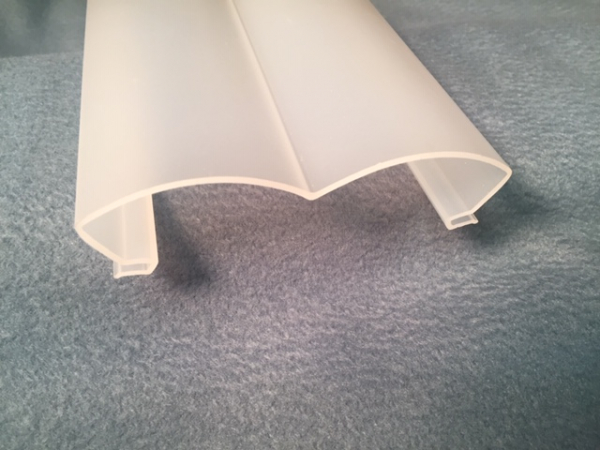

Extruded plastic lighting lenses easily install to either the bottom or side of a light fixture and are manufactured in clear and diffused options. Lighting extrusions provide beneficial light spreading and scattering benefits, while protecting lighting fixtures from dust, helping to conserve energy by providing more even lighting that reduces the need for additional fixtures.

Custom Extruded Lens Options

Extruded plastic lighting lenses are manufactured in lay-in, snap-in, clip-on, and other options to fit virtually any type of lighting.Common types of diffuser panels and plastic lighting lenses include:

- Light diffusers and lenses

- Display light covers

- Architectural Lighting

- Outdoor lighting lenses

- Low Bay lenses

- High Bay lenses

- Industrial lenses

- Retail lenses

- Commercial lenses

- Recessed lenses

- Surface mount lenses

- Refrigerated display lenses

Co-Extruded Light Lenses

Polycarbonate Diffusers vs Acrylic Diffusers

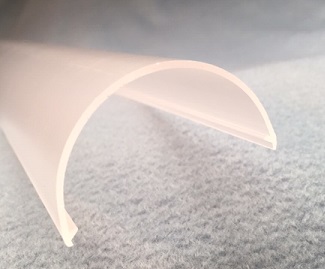

Polycarbonate diffusers and acrylic light diffusers are perhaps the most common types of diffuser lenses, though other materials, such as PVC may also be used. Extruded plastic lighting lenses come in a variety of shapes ranging from flat to contoured covers. Our custom-made lighting diffusers are manufactured in over 50+ frosted or clear extruded acrylic and can have colors, frost and texturing (such as ribbing and prismatic patterns), or films added to create a customized look.

Light Fixture Lenses

With our extensive materials knowledge and extrusion experience, Crescent Plastics can help you choose the right level of diffusion for your extruded LED lens and LED light diffuser acrylic or polycarbonate lens profiles.

We provide unmatched design support for numerous applications, including considerations for material blend, diffusion, efficacy, aesthetics, fit, and cost. We offer quick turnaround times on tooling projects.

We custom polycarbonate extrusions and acrylic extrusions with different levels of frost and diffusion from 50% to 95% light transmission. to provide the proper light transmission and hiding power for your extruded LED lenses. For additional “special effects,” we can also supply co-extruded LED lenses combining different colors or levels of diffusion.

Post time: Nov-05-2020