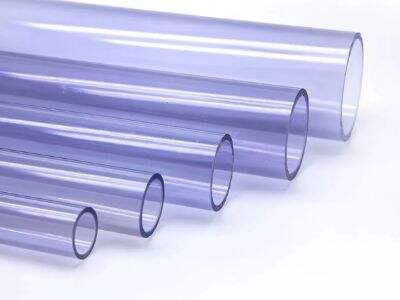

W tym świecie używamy wszelkiego rodzaju ciekawie kształtowanych rzeczy, a wyekstrudowane rury z plastiku to tylko jedna z tych fajnych obiektów, które wykorzystujemy z wielu powodów. Są one wykonane z różnych materiałów i mają wiele zalet. Przyjrzyjmy się bliżej tym fantastycznym rurom!

Jakie są surowce używane do produkcji wyekstrudowanych rur z plastiku?

Materiały takie jak PVC, polietylen i polipropilen mogą być wykorzystywane do produkcji wyekstrudowanych rur z plastiku. Różne właściwości każdego z tych materiałów czynią je odpowiednimi dla konkretnych zastosowań. Rury z polietylenu są cenne przy przewozie cieczy, ponieważ są elastyczne i odporne na chemikalia. Jednakże rury z PVC są mocne i trwałe: znajdują zastosowanie w materiałach budowlanych i sanitarce. Rury z polipropylenu są gumowate, lekkie i odporne na wysokie temperatury, stąd ich zastosowanie w opakowywaniu żywności.

Jaka jest aplikacja wyekstrudowanych rur z plastiku?

No cóż, wyekspresowane rurki z plastiku są wszędzie – w wielu miejscach i środowiskach pracy. Często są wykorzystywane w pakowaniu, budownictwie, samochodach i medycynie. W pakowaniu te rurki przechowują i transportują ciecze, proszki i małe towary. W budownictwie pomagają w instalacji sanitarnej, przewodach elektrycznych i izolacji. W samochodach są używane jako przewody paliwowe, hamulcowe oraz do ochrony kabli. W medycynie służą jako katetry, kroplówki i narzędzia chirurgiczne.

Dlaczego Wybrać Wyekspresowane Rurki Plastikowe?

Wyekspresowane rurki plastikowe są stosowane w niektórych zadaniach z różnych powodów. Dużym powodem jest to, że te rurki są lekkie i elastyczne, co ułatwia ich przenoszenie i montaż. Są również trwałe i odporno na chemikalnie, więc trwają długo. Ponadto wyekspresowane rurki plastikowe są tanie i mogą być dostosowywane do określonych potrzeb. Są także bardziej przyjazne dla środowiska, ponieważ mogą być recyklowane i ponownie wykorzystywane.

Jak Pomagają w Pracy Wyekspresowane Rurki Plastikowe?

Wyciskane rury z plastiku pozwalają również przedsiębiorstwom na bardziej efektywną i szybszą pracę. Możliwość dostosowywania tych rur do różnych potrzeb jest jedną z kilku rzeczy, które czynią je odpowiednimi dla tak wielu różnych zadań. Są również łatwe w pielęgnacji i czyszczeniu, co pozwala ludziom na więcej pracy w czasie, oszczędzając mniej czasu. Ponadto, ponieważ wyciskane rury plastikowe mogą być łączone z wieloma różnymi akcesoriami i częściami, łatwo integrują się z innymi systemami.

Najważniejsze cechy wyciskanych rur z plastiku

Dlatego właśnie, wyciskane rury z plastiku mają wiele świetnych właściwości, które czynią je idealnymi do różnych zadań. Są lekkie, elastyczne i mocne, bardzo łatwe w użyciu, przenoszeniu i montażu. Są również odporne na chemikalnie, ciepło i uszkodzenia, co pozwala im trwać dłużej. Ponadto, wyciskane rury plastikowe są dostępne w różnorodności i są tanie, a także oferują opcję przyjazną środowisku, która jest użyteczną dla firm.

W skrócie, wyekstrudowane rurki z plastiku to produkty praktyczne, które oferują wiele zalet. Mogą być wykorzystywane w różnych zastosowaniach w kilku branżach i są produkowane z innych rodzajów materiałów. Firmy mogą korzystać z tych niesamowitych rurek, rozumiejąc materiały używane do produkcji rurek z plastiku wyekstrudowanego, gdzie są one stosowane oraz jak ciągle wspomagają niektóre prace. Następnym razem, gdy zobaczysz wyekstrudowaną rurkę z plastiku, przypomnij sobie wszystkie jej fantastyczne właściwości!